Switchgear

Design and Manufacture Services

Switchgear and Control Panels

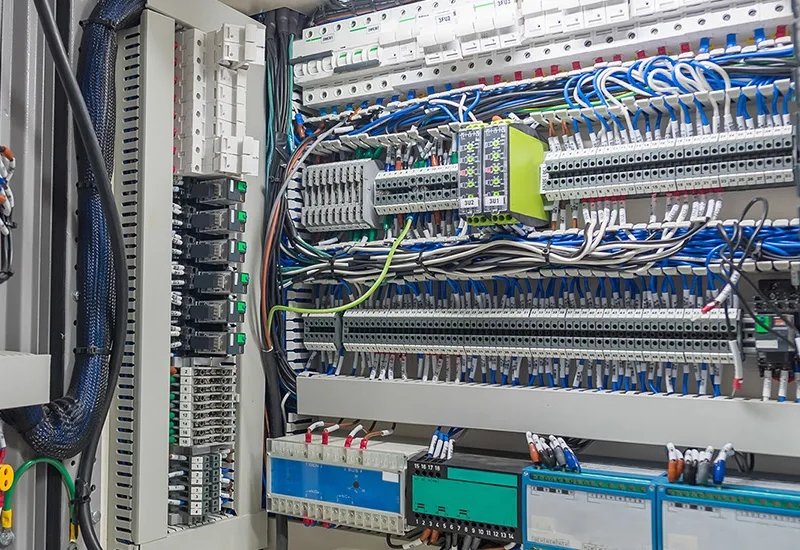

At our UK site, we take pride in manufacturing all our LV switchgear, control, and power panels in accordance with the latest specifications and industry standards – BS EN 61439 (IEC 61439) and IEC 60079 for Electrical apparatus for ATEX areas. Our switchgear and control panels are designed for efficient and reliable power distribution in a variety of environments.

To provide flexibility and convenience to our clients, we offer both onsite and remote Factory Acceptance Testing (FAT) facilities. This allows you to witness and verify the performance and compliance of the equipment, ensuring that it meets your specific requirements before installation.

Our electrotechnical and panel design and manufacture services utilises the latest design software to ensure precise and efficient wiring diagrams that can be shared in electronic formats typically DWG/DXF/PDF/SLDPRT. We can support customers by undertaking site surveys for standard and bespoke LV switchgear installations.

Moorcroft uses components from leading manufacturers and ensure parts installed meet current EN/IEC standards. To ensure safety, reliability, and functionality standards Moorcroft will provide a Certificate of Conformance (CoC) which evidence of compliance to customers and regulatory bodies in line with IEC 61439.

Sectors and Range of Support

We operate across a wide range of industries, providing expert support for LV switchgear assemblies in compliance with UK and EU regulations (BS 7671, EN 60204-1, IEC 60364). Our systems are engineered to deliver dependable power distribution and automation tailored to your needs.

Our solutions cover the following voltage ranges:

Low Voltage (LV)

50V to 1,000V AC or 120V to 1,500V DC

Extra-Low Voltage (ELV)

Below 50V AC or 120V DC

Our expertise includes:

✔ HVAC Control Panels

✔ Industrial Switchgear

✔ Process Control Panels

✔ SCADA (Supervisory Control and Data Acquisition)

✔ PLCs (Programmable Logic Controllers)

✔ Distribution Panels

✔ ATEX Control Panels (Explosive Atmospheres)

✔ Instrumentation Panels

✔ MCC (Motor Control Centre)

✔ MCP (Motor Control Panel)

✔ Outstation Panels

✔ Operator Control Stations

✔ BMS Control Panels (Building Management System)

✔ BeMS Control Panels (Building Energy Management System)

✔ BECS Control Panels (Building Energy Control System)

✔ HMI (Human-Machine Interface)

Thermal Testing

Thermal testing is a critical requirement in IEC 61439 to ensure the safe operation of low-voltage switchgear and control gear assemblies under operating conditions. It is important to verify that the assembly can handle its rated current without excessive temperature rise, which could compromise safety, performance, or longevity.

Moorcroft is accredited to ISO17025 to undertake thermal surveys to ensure design and functional compliance with temperature rise limits. This accreditation can be undertaken following assembly or if required following panel installation. Thermal surveys can also be used to establish performance of existing panels under operation loads.

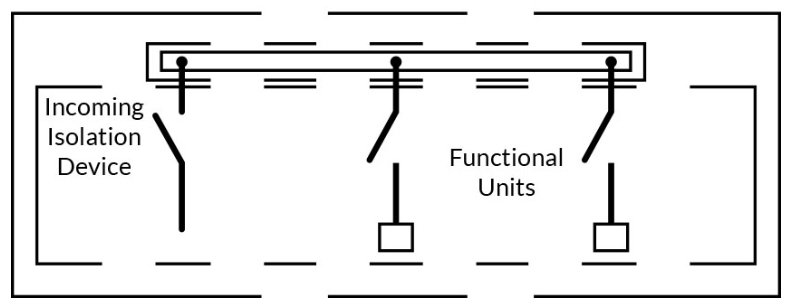

Forms of Separation

EN61439-2 dictates the internal separation of control panels by partitions referred to as form types.104.

The design phase concerns the selection of correct separation applicable to the end user application.

During the design phase we incorporate features to ensure compliance with IP rating and Electrical protection.

We can assist with incorporation of safety equipment such as surge protection devices (SPDs), overcurrent, earth fault and safety e-stops.

Basic non-critical

Form 1 Panel

No Separation

HVAC and Control

Form 2 Panel

Busbar Separation

Safety & Reliability

Form 3 Panel

Functional Separation

Critical Systems

Form 4 Panel

Full Separation

Modifications and Panel Upgrades

We offer expert solutions for upgrading, enhancing, and expanding existing systems—either onsite or at our specialist assembly workshop.

Our tailored approach helps customers increase system capability, comply with the latest safety regulations, and optimise existing installations, all while minimising business disruption.

Our Upgrade Process

At the design stage, we collaborate closely with clients to determine the most efficient upgrade strategy. Wherever possible, we aim to retain high-value components, ensuring cost-effectiveness while improving system performance. Most projects begin with a detailed panel survey and a full assessment of existing control points.

Our expertise includes:

✔ HVAC and control system modifications

✔ Automation enhancements

✔ SCADA system installation

✔ Controller expansions and upgrades

✔ Safety and compliance improvements

✔ Decarbonisation and energy efficiency projects

✔ Obsolescence management and replacement of outdated controllers

✔ Integration of Variable Speed Drives (VSD/VFD) for energy savings

✔ Updating wiring diagrams and O&M documentation